The starting gate…

Building an arena can be a daunting thought, especially when it’s for your beloved horses – you want to make sure that you’re doing right by both them and your pocket. Unfortunately, there is no one-horseshoe-fits-all, nor are there any shortcuts when it comes to constructing an arena – so before you set off quicker than Frankie Dettori racing Enable, there’s a few things to consider first.

Some of the key things to factor in are; Size, Cost, Drainage and Surface. Planning your project first, right through to completion, and having these key components ready, can help the smooth running of construction and prevent costs from creeping up. Don’t worry though, whether you’re starting from square one or upgrading an old arena, you’ve already started in the right direction by being here reading this. So, pop the kettle on, grab a notepad and we’ll get started…

Size does matter…

Now, probably quite obviously, the size of your arena will impact the total cost – a small lunge pen is going to be significantly cheaper than a 40 x 60 metre arena. When deciding on the size, consider the following;

Your land and current structures may affect where you choose to build – consider building in a previously constructed barn, or perhaps higher up a hill so as to help drainage, do you possibly already have a (even partially) levelled area as this would reduce slightly on the excavating.

The use of the arena once completed – are beginners/amateur level riders going to be the main users and therefore a smaller arena would fit the purpose, or do you require competition size to accommodate more advanced riders.

Your access to the site – if you have plans for a big arena yet only limited access, this will not only add to the time the process takes, but to the overall cost too.

Money makes the world go round…

Cost is a major factor and knowing your budget will significantly impact your entire project. Once you start to add up the costs you may find yourself starting back at step one a couple times, revaluating parts of your project with a little trial and error. This is why pre-planning is crucial…otherwise you may end up with a half build arena with no pocket money left and having to sell all your ‘matchy-matchy’ sets to try complete it – heaven forbid! Don’t be disheartened or try rush this step, as working back through and adapting the project is a good sign that you’re onto the right track.

As mentioned, remember to consider your access to the area. If you’ve limited access then suppliers will struggle to use their normal delivery vehicles and building machinery, meaning smaller loads in more frequent trips. Having to use smaller machinery to complete the arena will not only delay the process, but add to the cost significantly.

We often recommend to our customers with poor access to ask neighbouring farmers (or similar) if they can act as a safe drop off point. Farms often have great access for larger vehicles which will give you the cost reducing benefits of having your supplies dropped off in larger quantities, they also often have the lifting equipment to help offload and transport it to site. Although farmers are busy people and so are likely to charge for this however, it will still significantly reduce your time and money than using smaller vehicles with more trips.

We want an arena, not a swimming pool (although that would be nice too!) …

Your drainage system is paramount to the integrity of the structure of your entire arena, trying to drain away water without eroding the surfaces is a delicate procedure and without a sufficient system for this you also can’t guarantee an ‘all-weather’ surface. We strongly advise that you contact your local authority who can guide you as to where you can and can’t allow your drainage to vacate to.

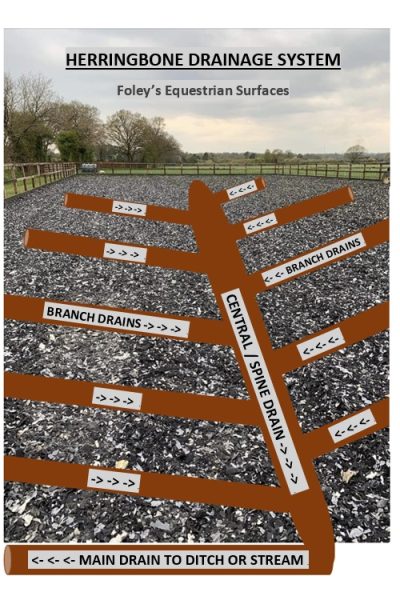

There are differing drainage systems and the one you use will be primarily based on what your surrounding area is like and what your arena purpose is. Any drainage system you use will follow the same construct of having collecting drains feeding a larger drain, this will in-turn carry the water away into a ditch or stream. The most common drainage system used in all-weather arenas is the ‘Herringbone Pattern’. This drainage system comprises of a perforated main drain running central of the arena with other, perforated but slightly smaller, drains branching off to either side. These drains should have a slight natural flow, be placed in a trench that is double the depth of the drain and then wrapped in a woven geotextile membrane – inadequately protected drains will quickly clog and fail, so this will help prevent anything other than water going into the drainage system.

Your arena should be pitched so that it only has to deal with rainfall/water from above (no water should be flowing from a higher part of ground and into the arena) and should be able to allow the water to flow gently and evenly away – if you can place your arena on higher ground, you will already be at an advantage for this.

Don’t forget to allow for water to drain when it comes to your kick-boards. The outer edge of your arena will likely get the most use, the last thing you want is water pooling in this area and unable to flow out – this will only increase your risk of damaging not only your surface, but the sub-layers too.